Have you thought about converting your garage into a comfortable space? Are you stumped about what to do with the cold uninsulated concrete floor? Insulate it quickly and cost-effectively with InSoFast insulation panels! InSoFast is an engineered continuous insulation that is easy to install on a garage floor.

Floor Preparations and Vapor Barriers

In older homes it is good practice to apply a concrete sealer to block moisture or install a vapor barrier on the concrete floor prior to installing the InSoFast panels.

If you have new construction with a vapor barrier already installed underneath the concrete slab, it is not necessary to put another vapor barrier on top of the concrete floor.

Using InSoFast on Both Walls and Floors

Install the InSoFast panels on the wall first. This minimizes the chance of water getting on top of the subflooring in the event the wall leaks.

Measure the floor-to-ceiling height to ensure you will have adequate clearance between the ceiling and the surface of the finished floor to comply with building codes. InSoFast panels alone will raise the floor by 2- to 2½-inches. Subflooring (a minimum of ½-inch is required on top of the InSoFast panels) and your choice of floor covering will reduce the clearance further, so plan accordingly for the best results.

Methods for installing the panel to the floor

There are four basic installation methods: floating, glue down, screwed down, and fully adhered. The floating method is recommended for carpet, laminate, and wood floors. This is a simpler, quicker installation that makes the concrete floor feel softer and more comfortable. The glue down method can be used for carpet, laminate, and wood floors. The screw down method can be used for any flooring type. The fully adhered method is recommended for tiled area to create a solid base that eliminates movement.

- Floating Installation

- The floating method places the panels directly on the concrete without any adhesive. Interlock the panels together with the tongue and grooved edges in a running bond or staggered pattern.

- Glue Down Installation

- The glue down method bonds the panels in place with a 3/8″ bead of PL Premium 3X Stronger Construction Adhesive along dove-tailed ribbing of each stud. One 28 oz. tube covers 50 s.f.

- Screw Down Installation

- Attach InSoFast panels to the concrete floor by installing concrete screws through the studs.

- Fully Adhered Installation

- Glue the panels studs to the floor with the PL Premium which is typical. Alternately for tile applications, the InSoFast panels can be set in a bed of compatible thin set tile adhesive with a notched trowel as per thin set manufacturer’s instructions.

Application options Interior Partition Walls

Install InSoFast panels up to existing interior partition walls. Non- load bearing interior partition walls can be framed directly on top of the subfloor or the InSoFast panel eliminating the need for a chemically treated bottom plate.

- Install the panels on the floor now there are three options for attaching the dividing walls.

- Place the base plate directly to the concrete floor, here treated lumber would be required if it comes into contact with the concrete. Cut and fit the InSoFast panels.

- Install the panels to the floor, attach the base plate to the InSoFast studs.

- Easiest method and best method would be install the panels to the floor, attach the sub floor to the studs, attach the base plate to the subfloor. This method reduces a lot of cutting and measuring.

How to Install Subflooring what kind of screw do I use?

Installing Subflooring

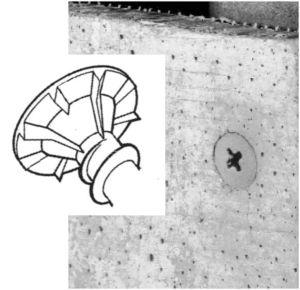

Install subflooring with a gap for expansion following per manufacturer’s instructions. Fasten with standard coarse thread all-purpose construction screws. Heavier subfloor panels you may need to predrill a countersink hole. A pilot hole to allow for the screw to be countersunk a flat-head screw to seat flush with the work surface.

Alternatively higher quality specialty fasteners for cement board applications can also be used saving a labor step when countersinking screws into the InSoFast stud.

When panels are installed as a floating floor, it is important to layout the subflooring so that the long seam of the plywood does not line up with the seams in the InSoFast panels. The short seams of the plywood should land over the top of a stud.

I have uneven garage floors what can I do?

Measure and make a template. Cellular PVC is a waterproof, rot proof shim material for supporting the InSoFast studs. Here we are using a make shift scribe to mark the cut on the PVC trim board.

Prior to installing panels, the low spots can be filled in with concrete patch/pea gravel or concrete floor leveler. Here is a video link to a typical self leveling floor system.

If you notice an area with excessive deflection after the subflooring has been installed, fill the void with adhesive or spray foam. Simply drill a hole through the subflooring and panel down to the void and inject PL Premium Construction Adhesive 3X or gap and crack spray foam. Using too much spray foam will cause a bulge in the floor. Avoid walking on this area until the adhesive or spray foam has set.

The Top 5 Things to Consider when insulating a garage floor

- InSoFast panels alone can raise the floor by 2 – 2½ inches which will affect any existing door swings as well as the floor-to-ceiling height.

- A subflooring layer of at least ½-inch will be required overtop the InSoFast panels.

- Code requires staircase steps to be all the same height to prevent tripping hazards. Measure your final heights accordingly.

- Water seeks the lowest point in your home. In basement flooring applications, always make sure you have a working sump pump or backflow prevention system to keep sewage from getting trapped in places you don’t want.

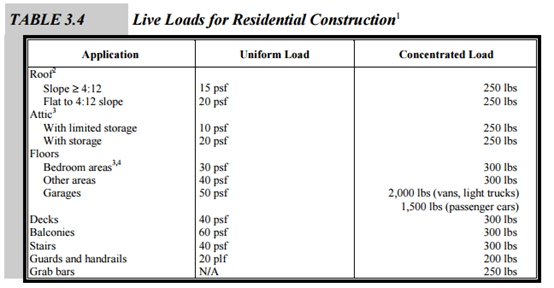

- Double check your local building codes to determine the allowable live load for construction. See the next section on calculating loads for more information

Can the InSoFast panels carry heavy floor loads?

Calculating Loads

You will need to determine what loading (weight per square foot) is acceptable for your local building codes.

For the most part, live load and dead load values for floor systems are considered “distributed loads.” The total weight is distributed or shared uniformly by the members in the floor system. InSoFast panels are uniform because they have 100% contact with the concrete and subflooring.

Our product testing determined that InSoFast panels can support 13 lbs per square inch of compressive resistance at 10% strain deformation. This equates to 1872 lbs per square foot for the design load, well within most residential construction specifications.

Table 3.4 is taken from the U.S. Department of Housing and Urban Development Office of Policy Development and Research’s