Insulated Studs

We understand the initial concerns people have in learning our panels’ structural stud framing is hidden…and that it’s designed to be glued, screwed, or nailed to almost any surface. It’s no small matter,-to perfect the multiple engineered features that make our panels so dependable, including the stud load capacity.

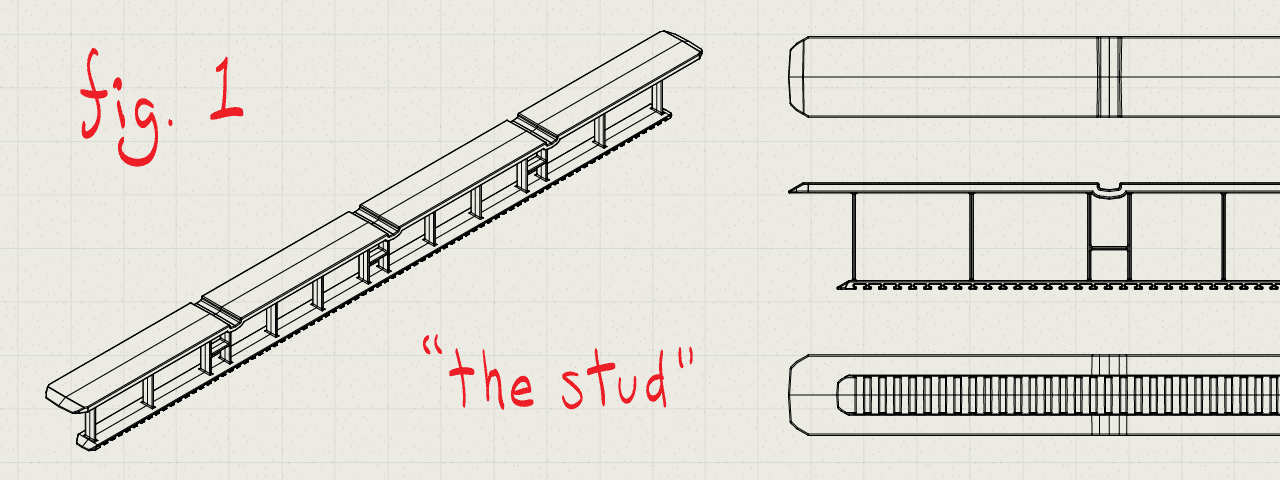

The Insulated Stud

The InSoFast panel studs provide a simplified approach to wall assembly. The InSoFast stud are injection-molded high-strength recycled polypropylene plastic. Next a special co-molding process expands the foam insulation around the studs forming one solid panel. The studs provide a structural attachment point to the substrate and for the specified finishes.

Reduces Construction Steps

One Part Not So Many Pieces

InSoFast panels reduce the complication of building an exterior wall assembly with an all-in-one rainscreen and insulation solution.

- Simple to install

- Molded into panel

- Stud framing included attach any finish

- Why handle all those parts?

- Why work so hard?

The easiest way to install a continuous insulated wall system.

Holding Power

How things stay in place?

The information below is an in-depth examination of the numbers behind our test reports. We’ll explain how strength is determined in construction, draw comparisons to traditional materials and describe how you can achieve the best performance from our studs.

Our panels are made of two materials: EPS foam and polypropylene plastic. The EPS foam forms the body of the panel and the stud acts like a regular studs when it comes to attaching finish materials, siding, stucco, stone, or cabinets and TVs. The embedded studs can be nailed, screwed, and glued. The studs do not split, rot, rust, or lose strength over time.

What metrics are used to determine strength in the InSoFast stud?

The independent Stork Twin City Testing Corporation measured adhesive capacities in their report. We received a Technical Evaluation Report from Intertek, a leading quality assurance testing corporation. Among other things, the report includes measurements on mechanical (screw and nail) capacities.

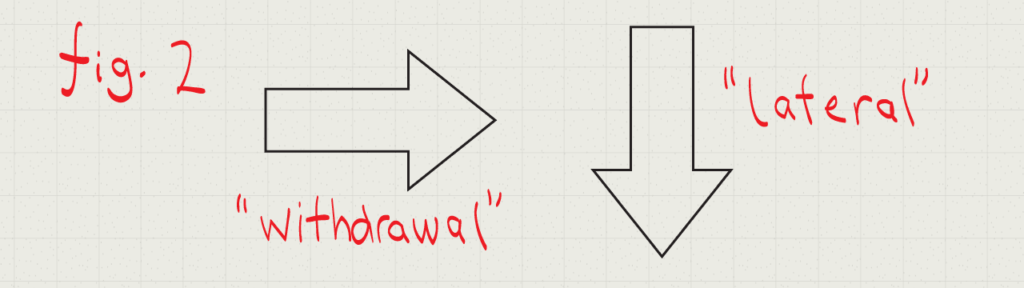

The reports focuses on two specific metrics for testing stud strength, Withdrawal and Lateral Strength. Withdrawal Strength is the capacity of the stud to hold weight without pulling the screw directly out of the material. Lateral Strength, or Shear Strength is the capacity of the stud to hold weight.

| Property | ASTM | Result |

|---|---|---|

| #6 1¼in Standard Drywall Screws Pull Out (Fastener Withdrawal) | D1761-06 | 325.4 lb/ft |

| #6 1¼in Standard Drywall Screws Shear (Lateral Screw Resistance) | D1761-06 | 470.6 lb/ft |

| Adhesion of PL Premium Adhesive and Stud (Peak Stress) | D4541-02 | 108psi (972ps/lf) |