Option 1 – Insulating the Bottom Rail

Insulating the Bottom Rail of a Shipping Container

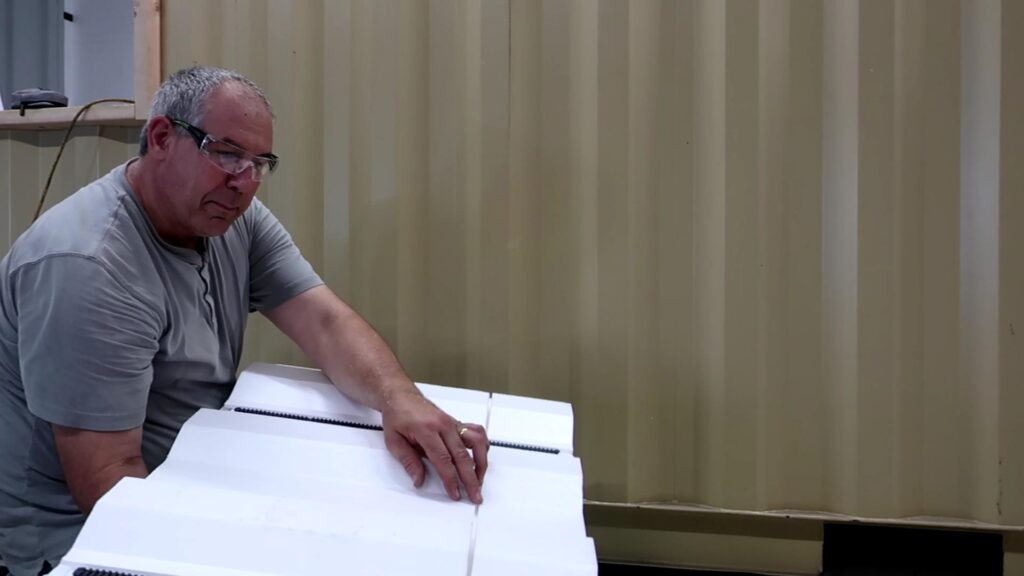

Insulating the bottom rail of a container presents a unique challenge because the rail is perpendicular to the shipping container’s corrugated side walls. InSoFast CX Container Panel are designed for the side walls of most shipping containers. In this video above Ed explains a novel approach to filling in a hidden airspace at the bottom rail with reverse cutting of the CX Panel.

Cut a CX44 panel to fit into the rail.

At a table saw dado a cut into the panel deep enough to encapsulate the top of the rail into the CX 44 panel. You may need to cut the face off of the fill in piece to fit snuggly and full support the full panel with the dado cut.

Additional modification to the panel may be neccessary. Here we removed a 1/2″ square to fit over square tube corner.

Finished Detail

Option 2 – Insulating the Bottom Rail

This approach works well and it is a little bit more robust of a detail with the 2 by lumber providing a harder impact surface. This detail is better suited for reatail rental fleets.

Adhesively apply a filler insulation panel that will give you a flush finished surface.

Mechanically attach the 2 by material through the foam and into the bottom rail.

Finished Detail Cross Section