Shipping Container Insulation and Framing

InSoFast brings our specialized expertise in building insulation, thermal envelopes, to the shipping container fabrication industry. We offer innovative shaped insulation and framing specifically engineered to fit shipping container builds. This reduces hidden steel wall condensation issues by filling and sealing the wall from moisture and temperature fluctuations.

Where to start

Verify Container Corrugations Before Ordering

Before You Order

Surprise, not all containers are the same size and size matters. The corrugation design for the side walls of shipping containers VARY. If you are unsure of the fit, order a container sample. The CX 44 panel adheres to the industry standard of 11″ on center a repeating pattern of the corrugated sidewall. Not all containers follow this pattern.

Shipping container dimension vary. It is important that you verify proper sizing before you order. To check our standard sizes click here.

Depending on your container’s condition and end results you want to achieve, we can guide you to the best approach, which insulation panels, insert and/or insulated studs to use.

- The condition that your shipping container is in, matters?

- If you are trying to save money buying a container in “vintage condition,” you may save money on the initial cost of the container but increase your labor costs.

- Shipping container sidewalls are built on an 11″ on center corrugation.

- Note this differs from standard framing construction methods built around 16″ or 24″ on centers. This affects other finish materials waste factors and attachment methods.

- The CX44 Panel stud spacing is 22″ on center this effects the finish materials installation methods.

- (E.G. a sheet of drywall 48″ x 96″, 22″ on center does not divide evenly into 48 or 96.) The fastening and adhesive patterns will change and finish material waste should be considered.

- We have alternate methods that fit the 4×8 USA and Canadian standards. See FP-2.0RW Surfaces

Questions that guide you to the right decision

- What do you want to achieve when you are finished, the end result?

- Residential, Commercial, Industrial, storage, etc.

- What surfaces do you need to frame and insulate?

- Interior application?

- Exterior application?

- How much insulation do you need?

- What “R-Value” is required for your project?

Obstacles, like building code requirements

BEFORE you place an order with us talk to a design professionals and your local building code officials. Before you purchase your container is the best time to to discuss regulations, permits, and codes surrounding container building in your area. Different locations have different sets, of rules, zoning and building permit requirements.

- Definition of Requirement – (a thing that is compulsory; a necessary condition.)

Helpful Resources:

- Building energy code requirements.

- Modular Building Institute and National Portable Storage Association, Compliance Handbook. This is outline for the IAS, International Accreditation Service, AC786 Criteria for Container-Based Structures.

- InSoFast Nationwide Code Compliance Report

What end result do you want to achieve?

Define your Scope of work

These pages can help you refine your needs, if you have questions give us a call @ 888-501-7899

Finally, make a plan and stick to it don’t over-estimate your needs. Measure twice order once.

Define Project Scope

Finished Interior/Exterior Space

Finished Interior Space; habitable, suitable to live in. This would be walls that would achieve higher R-Values, and would require planned services like electric, plumbing, windows and door openings and higher-grade finishes and cabinetry.

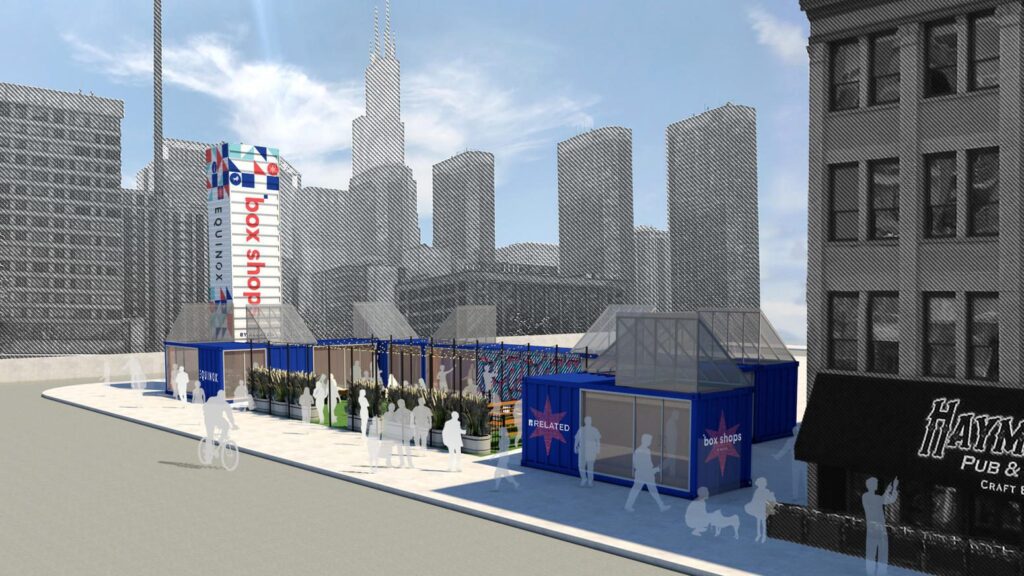

Commercial Interior/Exterior Space

Commercial Interior/Exterior Space; office spaces, commercial spaces, retail pop-ups and other high-end habitable spaces. These would be walls that would achieve higher R-Values, and planned services like electric, plumbing, windows and door openings and higher-grade finishes and cabinetry.

Industrial-Agricultural Spaces

Industrial-Agricultural Interior/Exterior Spaces; These would be walls where interior space is at a premium and services like electrical can be surface mounted. Insulation values can vary but a clean and durable finish materials like FRP fiber reinforced plastic or metal are desirable.

Exterior Finishes

InSoFast is a stable insulation panel that will work well with most exterior finishes. Stucco, thin veneer stone, weathered steel siding, and board and batten siding’s to name just a few finishes. The insulated framing systems allows the designer a wide range of options. The air tight, water tight, and 100% adhesive application, the steel shell need not be compromised with hundreds of screws holes just attaching the exterior finishes.

The weathered steel we chose is heavier than most available material siding. Weathered steel, often referred to as *(Cor-Ten). Corten develops a light rust layer that once formed, will protect the underlying material and prevent further corrosion. That is why we chose it for this InSoFast project we are hoping for a dramatic yet rustic finished shipping container.

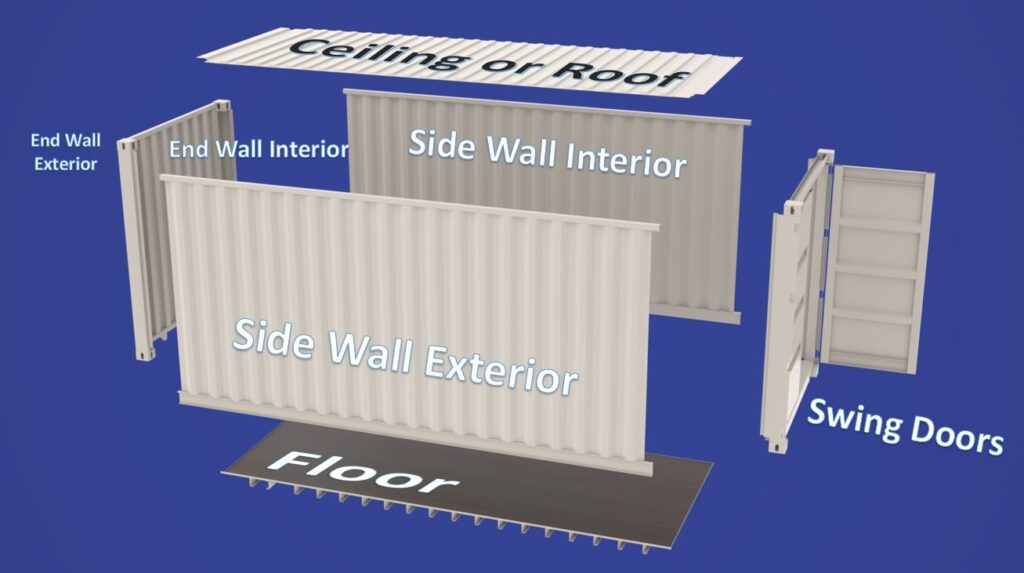

Definitions, Standards and Terminology

Surface Definitions

A container is a cube with 6 sides, each side has 2 surfaces that can be framed and insulated. Added together interior and exterior, now the possible surfaces to insulate equals 12 sides with windows, doors, then R-Value the combinations are limitless.

Make a plan and stick to it don’t over-estimate your needs. Measure twice order once.

Abbreviations for Shipping Containers Condition

InSoFast Definition of Conditions

- New (one trip)

- Used (multiple trips minor dings and dents)

- Vintage (Used hard lots of damage)

It can be very confusing purchasing new or second hand container. Every supplier and reseller can grade conditions on a different scale of good, better, or best, ABC’s, 123’s, and other industry acronyms and certifications. The alphabetic soup of ratings. It all sound so complicated and confusing. Yet it is fairly simple, inspect your container before you make the investment. Would you buy a used car before you took it for a test ride? Take the time and visit your container reseller.

- Institute of International Container Lessors –The IICL sets repair standards, by which all repairs are carried out. IICL is the strictest standards for used containers. Tools and Guides.

- Cargo Worthy– CW Standard under which a used shipping container is deemed suitable for the shipping cargo. The CW or Cargo Worthy standard generally implies that the container has a valid CSC. That little plate attached to the container Convention for Safe Containers. Look for the latest inspection date.

- Wind & Water Tight – WWT a standard under which containers are literally “wind and water tight”. In short, if you lock yourself inside the container, you should not see any light coming through the panels or roof. WWT makes no reference to the quality of the under-structure.

- Convention for Safe Containers –CSC established in 1972 to promote and maintain a high level of safety of human life in the transport and handling of containers by providing generally acceptable test procedures and related strength requirements.

- International Standardization Organization – ISO International organization based in Geneva working towards harmonizing worldwide technical standards; including those governing the construction of shipping containers

Industry Standards Wall Preparation

Definition of Requirement – (a thing that is compulsory; a necessary condition.)

Safety Precaution: Cut out all openings in the container and complete all welding, cutting or grinding operations prior to installing InSoFast panels. Do not expose the foam insulation or plastic studs of InSoFast panels to the flames, heat or sparks generated by welding, grinding or cutting on the steel container after panels have been installed.

- Ensure all surfaces are clean of any debris, dust, loose paint, etc before installing InSoFast panels. It is up to the installer to determine the suitability of the adhesive for the surface you are bonding to. If in doubt, an adhesive performance test can be done.

- Eliminate any leaks before installing InSoFast panels. Do not penetrate the steel walls of your container with screws or fasteners. This compromises the continuous seal and can introduce moisture-related issues.

- If the container has large dented or indented areas, we recommend hammering them as smooth as possible before installing InSoFast products. As an alternative, the foam of the panel or insert can be adjusted by either carving away the InSoFast foam or by adding spray foam as as a dent filler.

- Cut out and frame all openings before installing any InSoFast panels or inserts.

Modular Building Institute and National Portable Storage Association, Compliance Handbook.

How to Choose the Best Container

If you are purchasing and converting a container for storage, a man cave, she shed, mobile office, or just insulated storage we recommend an in person visual inspection. It is okay to act like a Missourian, (the SHOW ME state). It would be easier to modify a container in good condition then one with dings, dents, rust, and holes.

It is important to inspect the walls you want to cover before you order InSoFast. InSoFast panels are not suitable for every project. It is up to you to decide if you have the skills necessary to tackle leveling a wall using advanced techniques. A wall must be repaired and stabilized structurally. Containers should be hammered flat and true and all rust spots and hole fixed. InSoFast panels are designed to be applied to structurally sound walls. How to shim and level walls. Learn More