Drywall and Other Finishes

Drywall, cement board, tile base, and wood siding can be installed over InSoFast panels in the same exact way it is installed over traditional wood framing. Simply attach drywall, cement board, tile base, or wood siding using all-purpose drywall screws or what the cement board manufacturers recommend. You should nail base and trim boards into the studs using trim nailer or hand nails.

Important: InSoFast panels, like all rigid foam insulation boards, are required by code to be covered by ½” drywall or any other approved 15-minute thermal barrier (IBC 2603.4). If using an alternative finish, check with your local building code official to make sure it meets requirements.

Things to keep in mind

- Always allow 24-hours for the PL Premium 3X Stronger Construction Adhesive to fully cure before attaching any finishes.

- Basement environments are prone to moisture. Be sure to research drywall best suited for your situation. Some variations include:

- Basement Drywall: typically has a mold-resistant paper

- Mold-Resistant Drywall: typically has both mold-resistant paper and gypsum core

- Paperless Drywall: typically a mold-resistant gypsum core with fiberglass

- Tile Backerboard: cement board substrate used as a tile backer

- When installing InSoFast in a corner, be sure to solid back edges that don’t end in studs. See below for more details

Drywall is installed over InSoFast panels in the same exact way it is installed over traditional framing. Simply attach drywall to the InSoFast studs using all-purpose coarse drywall screws. Type W Bugle Head Screws attach single layer gypsum panels to InSoFast framing. Screws provide greater holding power than wallboard nails, minimize popping and help prevent damage to the panels.

Follow the standards set forth by the drywall industry that the screw be at least a #6 x 1-5/8” long Phillips Drive Coarse Thread Drywall Screw for the Flat Panel UX2.0 and a #6 x 2” long Phillips Drive Coarse Thread Drywall Screw Flat Panel EXi 2.5. At a minimum the screw length should be long enough to pierce through the InSoFast stud 1/2″ so the tapered point is all the way through the stud.

This picture demonstrates the variety of fasteners that will work with the stud and not crack or split for a secure and positive attachment for the finishes.

Installing the Drywall

Depth Stop for Drywall

Drywall Screw Setters with your drill. They control the depth of the screw when driving in drywall, particle board and plywood.

Interior applications to attach drywall we recommend a coarser thread bugle head drywall screw. The length of the screw long enough that the sharp point is all the way through the stud.

If you are installing a hard surface material like finished plywood or cement board for tile or cultured stone you may want to consider using specialty fasteners like “ROCK-ON or BACKER-ON” to provide a screw head the has cutter bits to counter sink the material.

You should nail base and trim boards into the studs using trim nailer or hand nails.

Alternatively higher quality specialty fasteners for cement board applications can also be used saving a labor step when countersinking screws into the InSoFast stud.

When panels are installed as a floating floor, it is important to layout the subflooring so that the long seam of the plywood does not line up with the seams in the InSoFast panels. The short seams of the plywood should land over the top of a stud.

Securing Drywall near Outside Corners

- Use a metal corner angle (3″ x 3″, 25ga sheet metal) to wrap outside corners. Generally available in the roofing/flashing section of home improvement stores or drywall supply yards.

- Place beads of adhesive on the back side of the metal angle and press it against the corner. If necessary, hold the angle in place with duct tape.

- Hang drywall by screwing all-purpose drywall screws into the InSoFast studs and into the sheet metal corner angle. Install a second metal corner angle over the drywall using all-purpose drywall screws.

*Please note that although this is a video about installing drywall in a shipping container the metal corner utility angle will work for this application too.

Place a bead of adhesive approximately 1″ from each side of the corner. Press 2″ x 2″ – 25 ga. sheet metal angle into adhesive. Attach drywall by screwing into the metal corner angle. Nail into intersecting stud. Attach drywall by screwing into the metal corner angle.

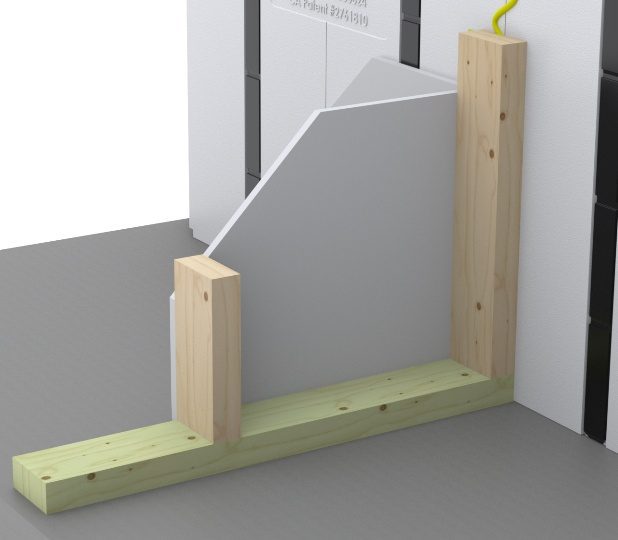

Attaching Partition Walls to InSoFast

Attaching a stud wall to the concrete base wall through the InSoFast panel with a long TAPCON Fastener.

Stem walls can be adhesively or mechanically (screwed) to the InSoFast panels stud.

Things to keep in mind:

-

- Allow 24-hours for the PL Premium 3X Stronger Construction Adhesive to fully cure before attaching any finishes.

Other links to get you started:

-

- Drywall Material Calculator: https://www.inchcalculator.com/drywall-calculator

- Drywall Material Calculator: https://www.homedepot.com/account/view/calculator/drywall

- Drywall Installation Cost Calculator: https://www.homewyse.com/services/cost_to_install_drywall.html

- Alternate Finished: https://www.insofast.com/explore/stone-and-stucco.html

Drywall Alternatives

Basically InSoFast is insulation and framing so there are very few limits to what you can use to cover and finish your project. If you can attach it to wood or steel framing you can attach it to InSoFast. Have fun and send us pictures.

There are numerous types of finishes that are designed for or can applied in moist basement environments. The following is a short list of examples and links to more information.

- James Hardie Tile Backer are decorative fiber cement boards.

- Magnesium Oxide (MgO) Board, a technologically advanced board with several superior features including mold-resistance and waterproofing.

- DensArmor Fiberglass Panels, a high performance gypsum panel wrapped in fiberglass for exceptional mold-resistance.

- Southern Wood Specialities offers kiln dried rough cut yellow pine ideal for rustic great rooms, “man caves”, game rooms, and cabins.

- FEMA Flood Damage Resistant Drywall (PDF, 627kb)

Important: InSoFast panels are manufactured using a flame retardant foam and are classified as rigid foam plastic insulation. They fall into the same class as pink, blue and yellow insulation boards which are required by code to be covered by ½” drywall or any other approved 15-minute thermal barrier (IBC 2603.4). If choosing an alternative to drywall it is important to check with your local building code official to make sure it meets your local requirements.

Nail Guns

Nail guns work well into the InSoFast stud. Always test your settings into scrap finish material and the stud before beginning on your wall. The stud is made of plastic make sure it is 55 degrees or above so not to crack the plastic when setting the nails.

This picture demonstrates the variety of fasteners that will work with the stud and not crack or split for a secure and positive attachment for the finishes.