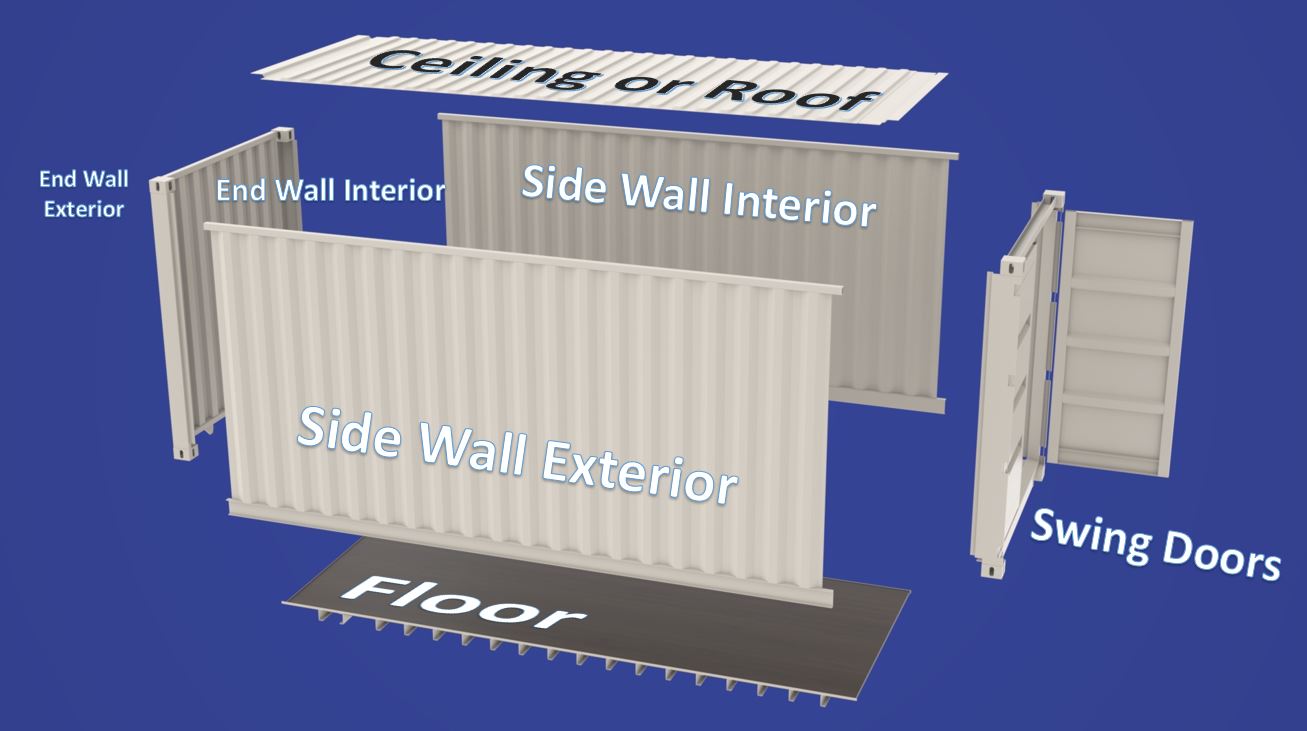

Sidewall (20' Standard) CX44-Bundle – View Product >Price: $ 730.00

This CX44 bundle assembly has enough material to finish one 20' standard container 8' side wall. The studs are 22 inches on center.

20' Standard 8' Sidewall Bundle - (CX44 -5 Boxes of 5 Panels)

(CX44 Insulated Panels = 25 panels) = 183 sq-ft.

Part Code: CONSWCX-5

Sidewall (20' High Cube) CX44-Bundle – View Product >Price: $ 730.00

This CX44 bundle assembly has enough material to finish one 20' High Cube Container side wall. The studs are 22 inches on center.

20' High Cube Sidewall Bundle - (CX44 -5 Boxes of 5 Panels)

(CX44 Insulated Panels = 25 panels) = 183 sq-ft.

SKU: CONSWCX-5

Sidewall (40' Standard) CX44-Bundle – View Product >Price: $ 1,314.00

This CX44 bundle assembly has enough material to finish one 40' standard container 8' side wall. The studs are 22 inches on center.

40' Standard 8' Sidewall Bundle - (CX44-9 Boxes of 5 Panels )

(CX44 Insulated Panels = 45 panels) = 330 sq.ftPart Code: CONSWCX-9

Sidewall (40' High Cube) CX44-Bundle – View Product >Price: $ 1,460.00

This CX44 bundle assembly has enough material to finish one 40' High Cube container side wall. The studs are 22 inches on center.

40 ' HC Side Wall Bundle - (CX44 -10 Boxes of 5 Panels )

(CX44 Insulated Panels = 50 panels) = 367 sq.ft

Sidewall (20' Standard) 2.0 Flat Panel-Bundle – View Product >Price: $ 732.00

Sidewall bundle for one side wall

This bundle contains:

2 (I-SWI) Side Wall Insert = 60 pcs.

4 (FP-2.0RW) 2" Flat Panel with raceways (5 panels/box) = 160 Sq.Ft.

SKU: CON-SWUX-20ST

Sidewall (20' High Cube) 2.0 Flat Panel-Bundle – View Product >Price: $ 860.00

Sidewall bundle has material to finish one sidewall

This bundle contains:

2(I-SWI) Side Wall Insert = 60 pcs

5 (FP-2.0RW) 2" Flat Panel with raceways (5 panels/box) = 200 Sq.Ft.

SKU: CON-SWUX-20HC

Sidewall (40′ High Cube) 2.0 Flat Panel-Bundle – View Product >Price: $ 1,592.00

Sidewall bundle for one side wall

This bundle contains:

4 (I-SWI) Side Wall Insert = 120 pcs.

9 (FP-2.0RW) 2" Flat Panel with raceways (5 panels/box) = 360 Sq-ft.

SKU: CON-SWUX-40HC

Sidewall (40' Standard) 2.0 Flat Panel-Bundle – View Product >Price: $ 1,354.00

Sidewall bundle has material to finish one side wall

This bundle contains:

3 (I-SWI) Side Wall Insert = 90 pcs.

8 (FP-2.0RW) 2" Flat Panel with raceways (5 panels/box) = 320 Sq.Ft.

SKU: CON-SWUX-40ST

Endwall (Container) 2.0 Flat Panel-Bundle – View Product >Price: $ 346.00

End Wall High Cube bundle is part of an assembly with enough material to finish the end wall of a High Cube container wall using the End Wall Inserts and a Flat 2.0 panels with studs.

This bundle contains:

1 (I-EWI) End Wall Insert Box = 20 pcs. 2 (FP-2.0) 2.0" Flat Panel = 10 panels (5 panels/box) = 80 Sq.Ft.

SKU: CON-EW

Ceiling (20’ Container) 2.0 Flat Panel-Bundle – View Product >Price: $ 604.00

Ceiling Insert bundle (CONCEIL-20 ) is part of an assembly with enough material to finish the ceiling of a 20′ container.

This bundle contains:

1 Boxes (CCEIL Inserts 57 pcs.) 4 Boxes (FP-2.0 Panels 5 each box ) = 160 sq-ft. SKU: CONCEIL-20

Ceiling (40’ Container) 2.0 Flat Panel-Bundle – View Product >Price: $ 1,208.00

Ceiling Insert bundle is part of an assembly with enough material to finish the ceiling of a 40′ container.

This bundle contains:

2 Boxes (CCEIL Inserts 57 pcs.) = 114 pcs. 8 Boxes (FP-2.0RW Panels 5 each box ) = 320 sq-ft. SKU: CON-CEIL-40

Floor (20’ Container) 2.0 Flat Panel-Bundle – View Product >Price: $ 512.00

The (FP-2.0) 2.0″ Flat Panel is versatile solution for container insulated sub-flooring.

This bundle contains:

4 (FP-2.0) 2.0″ Flat Panel = 20 panels (5 panels/box) = 160 sq-ft.

SKU: CON-FLOOR-20

Floor (40’ Container) 2.0 Flat Panel-Bundle – View Product >Price: $ 1,024.00

The (FP-2.0RW) 2.0″ Flat Panel is versatile solution for container insulated sub-flooring.

This bundle contains:

8 (FP-2.0RW) 2.0″ Flat Panel = 40 panels (5 panels/box) = 320 sq-ft.

SKU: CON-FLOOR-40

Swing Doors (Container) Flat Bundle – View Product >Price: $ 138.00

EX2.5 (FP-2.5) Panels for Doors

You need a minimum of 4-5 panels per door depending on the height of the container. Adjust your quantity to display the number of doors you need to cover, approximately 1 box per door.

Add On Door Option 1 box (Per Door)

Corner Post Endwall Standard-Bundle – View Product >Price: $ 167.00

Corner Post Insert is a 3 part per assembly for the inside corner end wall of a standard container.

End Wall Corner Inserts contains:

8 pcs of custom shaped foam inserts - 45 1/4in long x 2in thick.

4 Metal "M" Angle Inserts – 45 1/4in long x 1 3/4 in wide legs

Corner Post Endwall High Cube-Bundle – View Product >Price: $ 207.00

Corner Post Insert is a 3 part per assembly for the inside corner end wall with Add-On extensions for High Cube Containers.

End Wall Corner Inserts contains:

8 pcs of custom shaped foam inserts - 45 1/4in long

4 pcs of custom shaped foam inserts - 12 1/4in long

4 Metal "M" Angle Inserts – 45 1/4in long x 1 3/4 in wide legs

SKU: CON-EWCP-HC SKU: CON-EWCP-ST (Order Standard)